Material science has significantly advanced heat shield replacement materials for diverse sectors like aerospace, automotive, and industry. Researchers are developing eco-friendly alternatives using nanotechnology and polymer technology to create lightweight yet durable composites and refractories that offer superior thermal protection. Advanced ceramics, carbon composites, and hybrid materials are leading this transformation, promising enhanced performance in extreme temperatures. Nanotechnology and smart materials will further revolutionize heat shield replacement, offering ultra-thin coatings and adaptive materials for improved vehicle longevity and structural integrity.

The future of space exploration depends on innovative and sustainable solutions for heat shield replacement. As mission complexities grow, advanced materials science plays a pivotal role in developing heat shields with enhanced durability and lightweight designs. This article delves into cutting-edge materials like advanced ceramics, carbon composites, and smart nanostructures. Additionally, we explore efficient replacement techniques, including 3D printing, robotic welding, and automated repair systems. We also address sustainable practices and economic considerations to ensure environmentally friendly and cost-effective heat shield technologies for future missions.

- Advancements in Material Science for Heat Shielding

- – Exploring novel materials like advanced ceramics, carbon composites, and metal matrices with improved heat resistance and lightweight properties.

- – Discussing the role of nanotechnology and smart materials that can adapt to extreme temperatures.

Advancements in Material Science for Heat Shielding

Material science has witnessed remarkable advancements in developing innovative heat shield replacement materials for various applications. Researchers are exploring advanced composites and refractories that offer superior thermal protection while being lightweight and durable. These cutting-edge materials, often derived from nanotechnology and polymer technology, promise enhanced performance in extreme temperatures, making them ideal for use in aerospace, automotive, and industrial sectors.

The focus on sustainability also drives the search for eco-friendly heat shield alternatives. Engineers are developing bio-based composites and recycling techniques to reduce the environmental impact of traditional heat shield materials. This shift towards green technology not only benefits the planet but also opens doors for more efficient and cost-effective vehicle repair, including automotive collision repair and vehicle paint repair processes, by providing heat shielding solutions that meet both performance and sustainability criteria.

– Exploring novel materials like advanced ceramics, carbon composites, and metal matrices with improved heat resistance and lightweight properties.

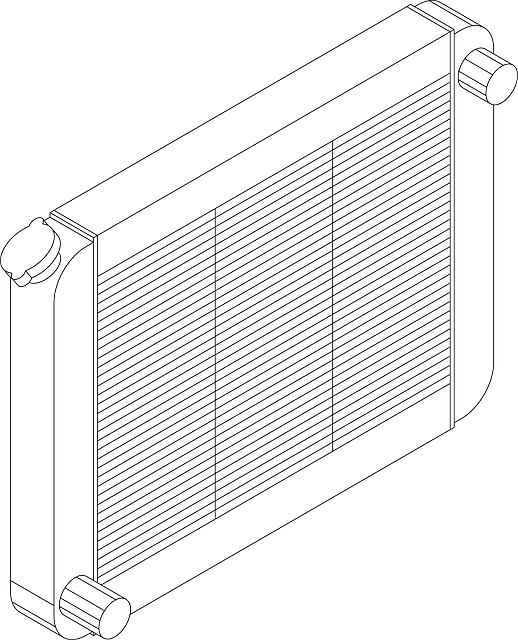

The future of heat shield replacement is poised for significant advancements with an exploration of novel materials designed to withstand extreme temperatures while maintaining lightweight properties. Advanced ceramics, for instance, offer exceptional heat resistance and low thermal conductivity, making them promising candidates for applications demanding superior protection against heat-related damage. Carbon composites, another innovative material, combine high strength-to-weight ratios with excellent temperature stability, further enhancing the capabilities of heat shield replacement technologies.

Furthermore, metal matrices impregnated with ceramic or carbon fibers are being developed to achieve both structural integrity and enhanced thermal endurance. These materials not only promise improved performance in heat shield replacement but also open doors for integration into various industries, including automotive (auto body repair, tire services), aerospace, and even industrial applications that require robust protection from high-temperature environments.

– Discussing the role of nanotechnology and smart materials that can adapt to extreme temperatures.

The future of heat shield replacement materials and techniques is poised for a dramatic shift with the advent of nanotechnology and smart materials. These innovative solutions promise to revolutionize car bodywork protection, enabling more efficient and adaptive heat management. Nanotechnology allows for the development of ultra-thin yet highly durable coatings that can withstand extreme temperatures, making them ideal for applications in aerospace and automotive industries.

Smart materials, designed to respond to environmental changes, offer another game-changing approach. These materials can expand or contract based on temperature fluctuations, providing dynamic protection against heat damage during high-performance driving or exposure to intense thermal events. Integrating these advanced materials into car paint services and body repair processes could significantly enhance the longevity of vehicle components, ensuring better protection for both passengers and structural integrity—a crucial aspect in maintaining top-tier car body repair standards.

The future of space exploration heavily relies on innovative heat shield replacement materials and techniques, driven by advancements in material science. As we venture further into uncharted territories, the need for lightweight, yet highly durable materials to protect against extreme temperatures becomes paramount. By harnessing the potential of advanced ceramics, carbon composites, and smart materials, we are paving the way for safer and more efficient spacecraft. These cutting-edge solutions not only promise to enhance heat shield performance but also open doors to new possibilities in space exploration, making every mission a step closer to success.